Straight Handpiece Maintenance Instructions

AUTOCLAVABLE HANDPIECES (Silver colored): SH26, SH27, SH28, SH29, SH31;

S, SP, Nose Guards; L, LP Long Nose Cones

Osada's spray oil is an autoclavable cleaner and lubricant. After surgery,

the handpiece (silver) must be separated from the micromotor (black), and

cleaned and lubricated with spray oil before blood or other fluid coagulates.

Steam autoclave the handpieces and autoclavable motor casings. No oiling

is required after steam autoclaving. Defective handpieces and micromotors

must be serviced at Osada.

(1) EXTERNAL CLEANING: Hold the handpiece under running water to wash

the surface debris and towel dry.

S/SP nose Guard 9cap): Pull off the cap from the body; wash separately and

towel dry; ready for (3) Steam Autoclaving. L/LP Long Nose Cone has embedded

bearings; separate the nose cone fron the body and go to (2) Spray oil.

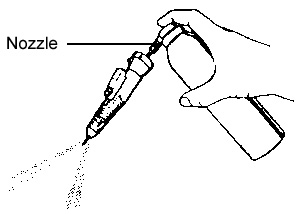

(2)

INTERNAL CLEANING WITH SPRAY OIL: Hold the handpiece in a paper towel;

insert the oil nozzle into the open end; spray oil to purge internal debris

(blood, etc.) until clean oil comes out of the opposite end. Wipe clean and

keep it upright on a paper towel to drain excess oil.

(2)

INTERNAL CLEANING WITH SPRAY OIL: Hold the handpiece in a paper towel;

insert the oil nozzle into the open end; spray oil to purge internal debris

(blood, etc.) until clean oil comes out of the opposite end. Wipe clean and

keep it upright on a paper towel to drain excess oil.

NOTE: spray oil penetrates better when a handpiece has a bur chucked

in, though higher pressure may be felt. Chucking mechanism (especially the

twist type) stays smooth and easy, if a bur is kept chucked in all the time.

(3) STEAM AUTOCLAVING: place the cleaned/oiled handpiece with a nose

guard in an envelope, keep it away from the wall in the autoclave, and steam

autoclave at 132 C for 15 min. followerd by a drying cycle. n autoclavable

handpiece stand may be used to keep the handpieces upright. No further oiling

is required.

DO NOT IMMERSE HANDPIECES IN DISINFECTANT SOLUTIONS. Stay away from

ultrasonic cleaners (immersion cleaner). Neither DRY HEAT nor CHEMICLAVING

is recommended. If the handpiece is autoclaved without proper cleaning and

oiling, severe damage may occur.

DO NOT AUTOCLAVE MICROMOTORS AND CORDS: only AMC/LAMC removable motor

casings are autoclavable. Handpiece/Micromotor/Cord may be gas-sterilized.

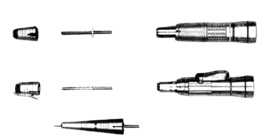

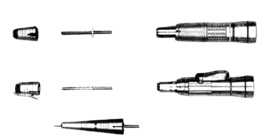

OSADA SH-SERIES STRAIGHT HANDPIECE WITH NOSE GUARDS

SH-Series Straight Handpieces must have removable nose guards: S (short)

and SP (short with pipe) with a silicone disc inside the cover, or L and

LP (long for 65mm or longer burs) with embedded bearings. Previous models

SH-132 and SH-032 have been retrofitted (when serviced) to have the same

feature.

With straight burs up to 65mm long the handpiece must have S or SP Nose Guard

to block debris from entering inside. The Nose Guard consists of a anose

cover and a small silicone disc, which are removable from the main body of

the handpiece for easy cleaning. Exchanging burs is performed without disturbing

the position of the Nose Guard.

The silicone disc must be replaced when it no longer rotates with the inserted

bur. Petroleum jelly on a new silicone disc will remedy the occasional squeaking

noise when the bur is in rotation.

With dental attachments (angles), pull out the nose cover and the bur with

silicone disc from the chuck, and attach the angle over the bare handpiece

nose. make sure to replace the nose guard when a straight bur is used.

DRY CLEANING (NON-SURGICAL): Occasionally wash the nose cover with

tap water and towel dry (a Q-tip may help). Clean the exposed handpiece with

a tooth brush. Do not allow any solution to seep into the seams.

Drill Handpiece Main

Page -

Contra Angle Handpiece Maintenance -

Straight Handpiece Maintenance

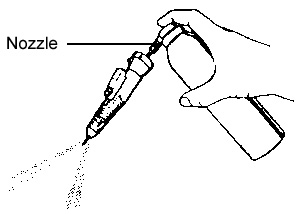

(2)

INTERNAL CLEANING WITH SPRAY OIL: Hold the handpiece in a paper towel;

insert the oil nozzle into the open end; spray oil to purge internal debris

(blood, etc.) until clean oil comes out of the opposite end. Wipe clean and

keep it upright on a paper towel to drain excess oil.

(2)

INTERNAL CLEANING WITH SPRAY OIL: Hold the handpiece in a paper towel;

insert the oil nozzle into the open end; spray oil to purge internal debris

(blood, etc.) until clean oil comes out of the opposite end. Wipe clean and

keep it upright on a paper towel to drain excess oil.